Corresponsables Interview with Chema Carrasco, CEO at Cartonplast

November, 2022

The main value we convey is the concept of Circularity, by which I mean the development of a packaging model that is genuinely sustainable.”

What is the Cartonplast mission-vision and the values it advocates?

Cartonplast is a European-wide, German multi-national. We have three plants in Spain and Portugal. At present, we are the plastic layer pad returnable packaging model leader, supplying the hollow glass sector basically for food and drink containers.

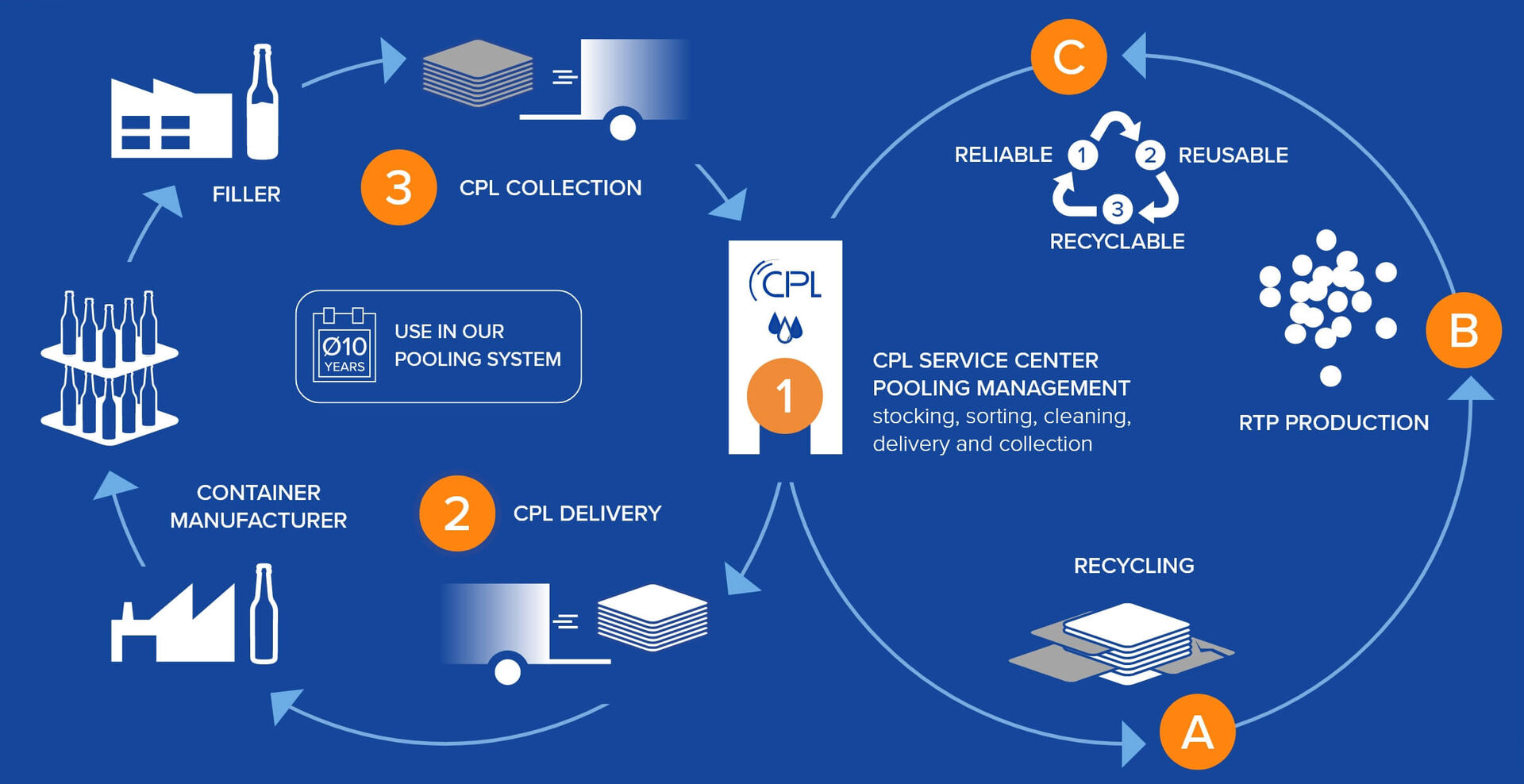

The main value we convey is the concept of Circularity, by which I mean the development of a zero-waste packaging model that is genuinely sustainable, based on the famous 3Rs: Reduce, Reuse and Recycle.

As far as the future is concerned, our company vision seeks to be able to continue providing this service in the glass sector. At present we command a market share of 80%. Though we are also interested in expanding into other areas with different products. Areas such as cans, which is a highly sustainable packaging option, not to mention other products, such as the plastic pallet, thereby doing away with the use of wooden ones, which would also impact on the carbon footprint.

How has sustainability developed in recent years up to the

present day?

We started 27 years ago. A few months ago, we celebrated our 25th anniversary which fell during the pandemic. Indeed, we took the opportunity to begin awarding the first prizes for sustainability. This is one of the levers we have to continue progressing towards the idea of circularity. Our company has developed and improved throughout; logistically, industrially and also, in human terms, which is a key company dimension.

When we started out in this business, 27 years ago now, single-use cardboard was used to transport all the hollow glass in this country, and everything that this brings with it, such as a complete lack of reuse and the amount of waste generated. In recent years, we have been penetrating the market by replacing this type of packaging with a new, reusable element.

What are the main pillars of the company’s corporate social responsibility and sustainability plan on which it bases its “green business” model? And can you share any of the company's Sustainability and CSR initiatives and projects with us?

Our company approach is circularity focused; something that is attracting the attention of a lot of organisations on account of the imminent regulations to be enacted and the new Royal Decree we are expecting on containers and container waste. In our case, circularity has been a byword at the company from the outset, when we started out on our journey 27 years ago.

The idea was to enhance the way our customers transport their containers. On the one hand, we sought to inculcate in them the concept of circularity which did not exist back then, while at the same time providing a service to enable them to concentrate on their business, which is the making of containers.

In recent years we have focused much more on this matter, concentrating on continuing to optimise the model with investments aimed at improving our carbon footprint, while also investing in the fitting of solar panels at our plants to reduce the energy impact. On the other hand, we have conducted energy efficiency studies on all our sanitising and layer pad lines. All reusable packaging material must be sanitised and washed.

We have invested over €2 million in our machines in the last few months this year and will continue to do so in 2023 to optimise our washing lines. Early next year we are going to set up one of these new lines at our plant in Portugal.

Lastly, logistics is one of the vital areas that we are working on, with a view to becoming more efficient by optimising routes, while at the same time seeking new methods of haulage, such as trucks that run on gas or hydrogen. Use of this technology is still at an early stage in Spain and Portugal, whereas in the rest of Europe, in Germany, it is quite advanced. Our goal for the next few years is to have most of this type of packaging material transported in trucks that use renewable energy.

One of our main actions has been to begin measuring our carbon footprint. We were very circularity focused but were not measuring the environmental impact caused by our activity. The aim is to better understand in which areas and points our carbon footprint can be enhanced. Simply taking time out to measure, understand and assess our carbon footprint has enabled us to identify where we can improve. For instance, engaging with more efficient and greener electricity companies from the energy perspective, or with optimal logistics services with respect to issues such as circularity and sustainability.

Looking forward, what are the main challenges facing

Cartonplast to meet 2030 Agenda goals?

Even before the United Nations SDGs, the company had taken on board a lot of these goals. We are particularly focused on SDG 12 Responsible Production and Consumption, SDG 13 Climate Action, specifically with respect to circularity. Indeed, in this regard we are also very active as regards SDG 17, seeking as we do Partnerships between companies to foster optimisation through circularity.

We approach these matters more as an opportunity than as a challenge. Cartonplast takes a very positive proactive approach in order to continue providing the best service to our current customers, as well as future ones in other sectors such as the canning industry or the PET one to transport their containers.